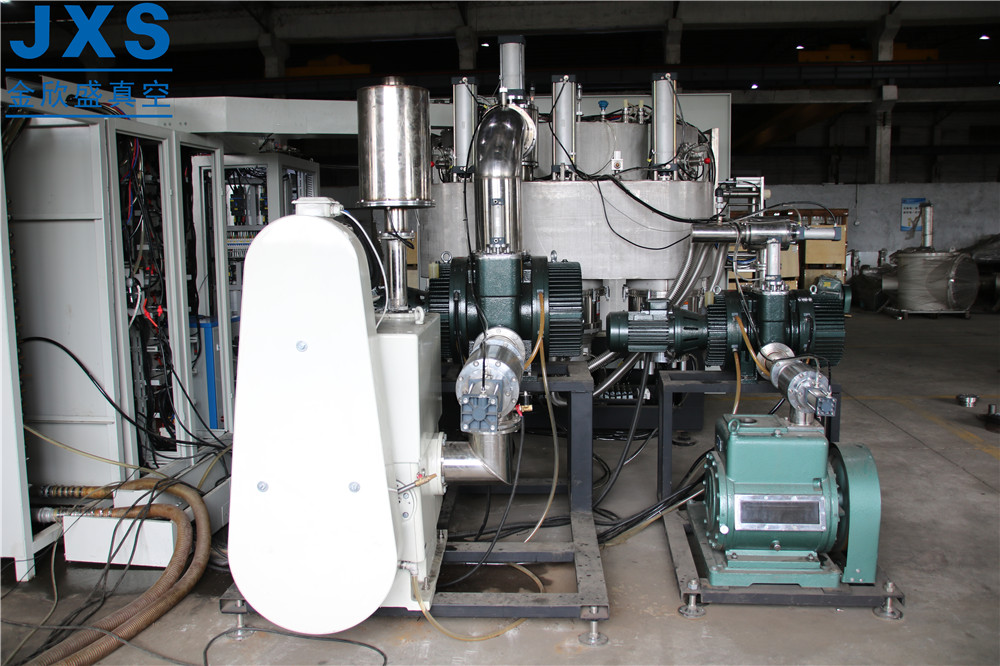

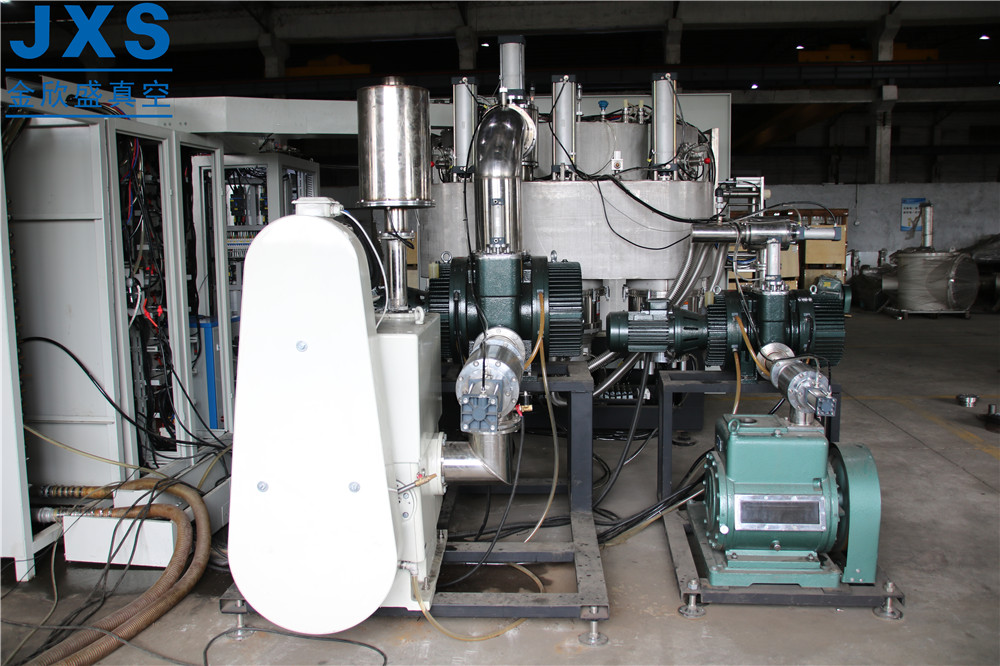

Vertical Full Auto Stainless Steel Watch PVD Sputtering Equipment

Main Configuration

| Vacuum Chamber Inner Size | Custom Made |

| Vacuum Chamber Material | Stainless Steel |

| Control System | Full Auto |

| Operation Way | Touch Screen |

| Heating System | 1 Set |

| Rotation Stand | 1 Set |

| Working Theory | Multi Arc+Magnetron Sputtering |

| Structure | Vertical Single Front Open Door |

| Warranty Period | 1 Year |

| Pump Combination | Mechanical Pump+Roots Pump+Diffusion/Turbo Pump |

As for stainless steel watch, we will use multi arc for base coating and magnetron sputtering for surface coating. That will make sure high energy efficiency. Vacuum chamber is to put product to coat, vacuum pump is to pumping air out of vacuum chamber, electrical cabinet is to control actions and provide energy. Except watch, we can also coat jewelry in such PVD sputtering equipment.

PVD Sputtering Watch

With the PVD sputtering technology, stainless steel watch can be coated into gold, rose gold, blue, gray, black and rainbow color. 1 set of PVD sputtering equipment can reach above colors. Such colors will enlarge watch using life and provide higher selling value with nice decorative function.

FAQ

What is lead time of PVD sputtering equipment?

60 working days.

What is trade terms?

EXW, FOB, CIF, etc.

How to create above colors?

By using high current to heat up metal target(titanium, TiAl, etc.) into ion, then react with different gas(Ar, N2, C2H2, O2) to deposit metal film on watch.